Advantages

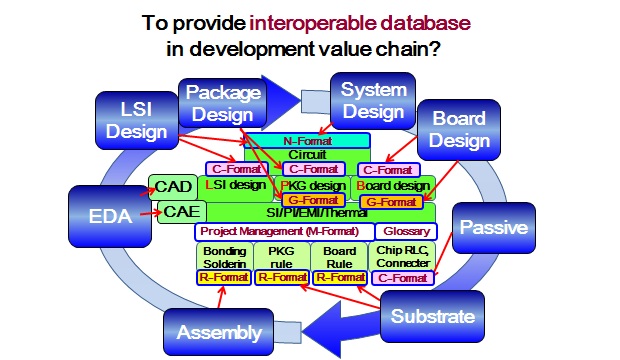

The conceptual design environment using LPB standard format

A common standard will facilitate the exchange of information so planning the entire design at an early stage can be realized. Post design analysis will be possible also in the whole of LPB. Analysis of the post design is examined in the whole idea of the design, to determine giving feedback of where in the appropriate design changes in LPB. This will promote the overall optimization. (Refer to figure above)

Visualization effect of LPB

The design time can be shortened by using the LPB format. As the traditional way, the design will start immediately after separating product planning individually, therefore exchanging information is limited. While trying to adjust the detailed design, design period gets longer. Optimization also tends to be a separate of each LPB. By using LPB format for distributing information, each technician of LPB will be able to have the same understanding of the challenges in early stage, therefore the adjustment at the stage of conceptual design can be done. By this, making clear the specifications, design target is decided, so the duration of individual designs can be shorten. It also has an effect of reducing the number of design iterations since the design quality is enhanced. LPB format can collect input information of design and simulation, therefore it can reduce setup time of design and simulation, as the result, development time can be shortened as a whole. LPB format can enable the entire analysis easily, s o that sufficient verification can be done, then the quality of set can be improved. So the period of adjustment in the set can be shorten and time to market can be accelerated(for reference diagram above). The design method with LPB format can be applied to the design environment for next product development.

Exchange information in supply chain

LPB standard format reveal what the information necessary. LPB designers need to obtain the information (such as design parameters and constraints) to develop competitive products. The required information must be shared and are provided in the supply chain.

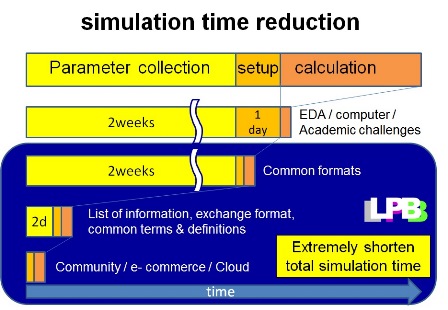

Simulation time reduction

Definition of simulation time is the sum of the calculated execution time and time according to the information collection and setup of the preparation phase. In order to reduce the simulation time, so far, has been focused on reducing the execution time calculation in the following way.

- EDA tool improvements

- I increase the processing power of the computer

However, the reality is more of preparation time's taking longer than the calculated time. LPB is it is the role of is to shorten the preparation time.

The following methods are effective to reduce the amount of time it takes to set up and information gathering time.

- The unified format to exchange information

- List the necessary information

LPB standard fomart are valid in these things.

It is possible to reduce further if there is a mechanism to exchange information. For example,

- Formation of a community for the exchange of information

- E-commerce

- Development of cloud database

LPB forum has been established for this purpose.